Hi Guys,

Following today's tutorial here is a link to a great set of Grasshopper tutorials:

http://elsewarecollective.com/AIR/Tutorial%20Videos/AIR_TutorialVideoList.pdf

I've gone through a bunch of these myself and found them to be really clear and inspirational.

Cheers

Sunday, October 27, 2013

Sunday, October 20, 2013

On Lazyness, Recycling, Sculptural Mathematics and Ingenuity

Hi Guys,

This title, by architects Neutelings and Riedijk, is on level 9 of the Main Library:

Title: El Corquis de Arquitectura.

Subjects: Architecture -- Spain -- Periodicals ; Architecture -- Periodicals

Description: Spanish and English, <1989->

Description based on: 19 (enero 1985); title from cover.

Publisher: Madrid, Spain : El Croquis,.

Date: 1982

Format: v. : ill. ; 33 cm.

Language: Spanish;English

Identifier: ISSN0212-5633;ISSN0212-5633

ILS API ID: NSW01000844777

Source: UNSW Aleph

Call number: 720.5/121 issue 94

I'll pop up this afternoon and scan the appropriate pages.

Cheers

This title, by architects Neutelings and Riedijk, is on level 9 of the Main Library:

Title: El Corquis de Arquitectura.

Subjects: Architecture -- Spain -- Periodicals ; Architecture -- Periodicals

Description: Spanish and English, <1989->

Description based on: 19 (enero 1985); title from cover.

Publisher: Madrid, Spain : El Croquis,.

Date: 1982

Format: v. : ill. ; 33 cm.

Language: Spanish;English

Identifier: ISSN0212-5633;ISSN0212-5633

ILS API ID: NSW01000844777

Source: UNSW Aleph

Call number: 720.5/121 issue 94

I'll pop up this afternoon and scan the appropriate pages.

Cheers

CNC Router Details

Hi Guys,

The CNC router at the Square House is a Roland MDX-550 and it uses a piece of software called the SRP Player.

SRP stands for Subtractive Rapid Prototyping.

There are videos tutorials online; this is one uploaded by the makers of the machine, Roland, http://www.youtube.com/watch?v=IwNbWbyWcL4

We can visit to take a look at the machine at 1pm today (Monday 21 October).

Cheers

The CNC router at the Square House is a Roland MDX-550 and it uses a piece of software called the SRP Player.

SRP stands for Subtractive Rapid Prototyping.

There are videos tutorials online; this is one uploaded by the makers of the machine, Roland, http://www.youtube.com/watch?v=IwNbWbyWcL4

We can visit to take a look at the machine at 1pm today (Monday 21 October).

Cheers

Thursday, October 17, 2013

More examples

Hi Guys,

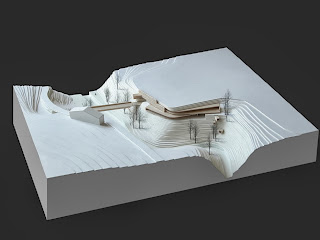

This is from one of the sites we looked at in class the other day: Le Container

A nice example of site and architecture coming together in a model.

and some other examples (just one with a site, but just to keep you thinking/inspired):

This is from one of the sites we looked at in class the other day: Le Container

A nice example of site and architecture coming together in a model.

and some other examples (just one with a site, but just to keep you thinking/inspired):

Tuesday, October 15, 2013

Filament for the 3d Printers

Hi Guys,

You can get your own filament for the 3d printers here:

https://www.bilbycnc.com.au/DispCat.asp?CatID=9&SubCatID=107

Its very reasonably priced and you can get a range of colours ... you might like to team up and share some different colours between a group of you?

Cheers

You can get your own filament for the 3d printers here:

https://www.bilbycnc.com.au/DispCat.asp?CatID=9&SubCatID=107

Its very reasonably priced and you can get a range of colours ... you might like to team up and share some different colours between a group of you?

Cheers

Sunday, October 13, 2013

Websites and Blogs from today's class

Hi Guys,

Choi sent me all of the blog's we viewed in today's class; I've put them in a new post so that they are a little easier to get to;

http://lecontainer.blogspot.com.au/

http://bldgblog.blogspot.com.au/

http://www.dezeen.com/

http://abduzeedo.com/

http://www.deathbyarchitecture.com

http://www.archdaily.com/

http://www.ted.com/

I encourage you all to visit them on a regular basis.

Cheers

Choi sent me all of the blog's we viewed in today's class; I've put them in a new post so that they are a little easier to get to;

http://lecontainer.blogspot.com.au/

http://bldgblog.blogspot.com.au/

http://www.dezeen.com/

http://abduzeedo.com/

http://www.deathbyarchitecture.com

http://www.archdaily.com/

http://www.ted.com/

I encourage you all to visit them on a regular basis.

Cheers

Wednesday, October 9, 2013

Laser cutting advice from Anthony Jones

Hi All,

Below is some advice from Anthony Jones (Design Lab) regarding problems you might be having with the new VLS3.50 laser cutter;

I would add that slowing the speed of the laser seems to have the greatest effect on cutting through the material, but be especially careful to ensure that any flames from the cut are sucked away quickly by the extraction unit ... we don't want those flames getting anywhere near the lenses and mirrors!

I've had reports back that 5mm MDF has been cut successfully, so its all in the settings.

Finally, I'll remind you that upping the material thickness beyond what the material actually is simply puts the laser out of focus and lowers its cutting performance, which upping the risk of fire, so don't be tempted to use that technique if your material isn't cutting.

Cheers

Below is some advice from Anthony Jones (Design Lab) regarding problems you might be having with the new VLS3.50 laser cutter;

·

Laptops are not connecting properly to the laser:

o The

connection problems could be due to:

-

not logged in to PC as ‘admin’ with full rights

-

incorrect model chosen during install

-

UCP installed, but actual ‘driver’ firmware not

being installed when laser connected (found new hardware wizard)

-

Won’t work with Mac, and Windows 8 may have ‘driver

not digitally signed’ errors

-

faulty or low-powered USB port

·

Material

is not being cut 100% of the way through:

o

Most

materials do vary a bit from their nominated thickness – solution is to

increase the power settings as follows:

-

in

the ULS driver, on the ‘Materials Database tab’, drag the intensity slider for

‘Vector Cutting’ till you get a result

that works.

I would add that slowing the speed of the laser seems to have the greatest effect on cutting through the material, but be especially careful to ensure that any flames from the cut are sucked away quickly by the extraction unit ... we don't want those flames getting anywhere near the lenses and mirrors!

I've had reports back that 5mm MDF has been cut successfully, so its all in the settings.

Finally, I'll remind you that upping the material thickness beyond what the material actually is simply puts the laser out of focus and lowers its cutting performance, which upping the risk of fire, so don't be tempted to use that technique if your material isn't cutting.

Cheers

Wednesday, October 2, 2013

Safe Working Procedure form to read

hi All,

Please download and read this form regarding the safe working procedure for using the VLS3.50 desktop laser cutter in room 2025:

HS026_Safe_Work_Procedure_Form_VLS350_RL.pdf

It goes over all of the items we covered in your training.

I'll have you sign my master copy next time I see you.

Cheers

Please download and read this form regarding the safe working procedure for using the VLS3.50 desktop laser cutter in room 2025:

HS026_Safe_Work_Procedure_Form_VLS350_RL.pdf

It goes over all of the items we covered in your training.

I'll have you sign my master copy next time I see you.

Cheers

Subscribe to:

Comments (Atom)