Hi All,

After speaking with Andrew Macklin I can confirm you have an extension until Monday 25th of November.

Cheers, and good luck for the final push!

Wednesday, November 20, 2013

Wednesday, November 13, 2013

Laser Cutter update

Hi All,

By now you've probably heard the laser cutter in room 2025 is out of action.

It appears that the number 2 mirror (on the left hand side of the machine) wasn't pushed all the way in and when the laser hit the side of it the coating was destroyed, then the housing was demagnetized resulting in the stray beam melting the y-axis drive belt.

The end result is we have a $850 repair bill.

It's going to be fixed on Friday morning ... so you'll get access again after that.

I'm going to speak to Andrew Macklin regarding a further extension so you can finish off well.

Please take extra care when replacing the mirrors after you've inspected/cleaned them; if you are at all unsure do not proceed ... contact me or Hank Haeusler.

Finally, as a reminder, always ensure the extraction unit is on before cutting.

Cheers

By now you've probably heard the laser cutter in room 2025 is out of action.

It appears that the number 2 mirror (on the left hand side of the machine) wasn't pushed all the way in and when the laser hit the side of it the coating was destroyed, then the housing was demagnetized resulting in the stray beam melting the y-axis drive belt.

The end result is we have a $850 repair bill.

It's going to be fixed on Friday morning ... so you'll get access again after that.

I'm going to speak to Andrew Macklin regarding a further extension so you can finish off well.

Please take extra care when replacing the mirrors after you've inspected/cleaned them; if you are at all unsure do not proceed ... contact me or Hank Haeusler.

Finally, as a reminder, always ensure the extraction unit is on before cutting.

Cheers

Friday, November 1, 2013

Laser cutter update

Hi All,

You'll be happy to know the laser cutter is working exactly as expected. Today students were cutting plywood and acrylic with no trouble at all. There was a lot of rastering going on too ... with some nice results.

The problem seemed to be that it was out of alignment ... going through a full alignment setup got it back to factory specs. My guess is this happened when I shifted the gantry with the machine being switched on.

Another thing to note is that the lens has a fracture in it (the technician showed me this last time he was here). This means that it has gotten dirty and the laser has heated up the glass lens rather than passing through it. They are about $500 to replace. With its current performance being ok we'll keep going with it as it is. But please remember to check the lenses and mirror every time to ensure they aren't dirty ... and if they are, please clean them before use (you will need to wait until they cool down if the machine has been in use ... say 5 minutes after use ... before you apply the cold fluid or this may crack the lens too).

Cheers, have a good weekend!

You'll be happy to know the laser cutter is working exactly as expected. Today students were cutting plywood and acrylic with no trouble at all. There was a lot of rastering going on too ... with some nice results.

The problem seemed to be that it was out of alignment ... going through a full alignment setup got it back to factory specs. My guess is this happened when I shifted the gantry with the machine being switched on.

Another thing to note is that the lens has a fracture in it (the technician showed me this last time he was here). This means that it has gotten dirty and the laser has heated up the glass lens rather than passing through it. They are about $500 to replace. With its current performance being ok we'll keep going with it as it is. But please remember to check the lenses and mirror every time to ensure they aren't dirty ... and if they are, please clean them before use (you will need to wait until they cool down if the machine has been in use ... say 5 minutes after use ... before you apply the cold fluid or this may crack the lens too).

Cheers, have a good weekend!

Extension for Assignment 3

Hi Guys,

Flowing on from the setbacks earlier in the semester some of you have requested an extension for assignment 3. this seems perfectly reasonable to me, so your new date for submission is Monday 18th of November.

Cheers

Flowing on from the setbacks earlier in the semester some of you have requested an extension for assignment 3. this seems perfectly reasonable to me, so your new date for submission is Monday 18th of November.

Cheers

Sunday, October 27, 2013

Grasshopper link

Hi Guys,

Following today's tutorial here is a link to a great set of Grasshopper tutorials:

http://elsewarecollective.com/AIR/Tutorial%20Videos/AIR_TutorialVideoList.pdf

I've gone through a bunch of these myself and found them to be really clear and inspirational.

Cheers

Following today's tutorial here is a link to a great set of Grasshopper tutorials:

http://elsewarecollective.com/AIR/Tutorial%20Videos/AIR_TutorialVideoList.pdf

I've gone through a bunch of these myself and found them to be really clear and inspirational.

Cheers

Sunday, October 20, 2013

On Lazyness, Recycling, Sculptural Mathematics and Ingenuity

Hi Guys,

This title, by architects Neutelings and Riedijk, is on level 9 of the Main Library:

Title: El Corquis de Arquitectura.

Subjects: Architecture -- Spain -- Periodicals ; Architecture -- Periodicals

Description: Spanish and English, <1989->

Description based on: 19 (enero 1985); title from cover.

Publisher: Madrid, Spain : El Croquis,.

Date: 1982

Format: v. : ill. ; 33 cm.

Language: Spanish;English

Identifier: ISSN0212-5633;ISSN0212-5633

ILS API ID: NSW01000844777

Source: UNSW Aleph

Call number: 720.5/121 issue 94

I'll pop up this afternoon and scan the appropriate pages.

Cheers

This title, by architects Neutelings and Riedijk, is on level 9 of the Main Library:

Title: El Corquis de Arquitectura.

Subjects: Architecture -- Spain -- Periodicals ; Architecture -- Periodicals

Description: Spanish and English, <1989->

Description based on: 19 (enero 1985); title from cover.

Publisher: Madrid, Spain : El Croquis,.

Date: 1982

Format: v. : ill. ; 33 cm.

Language: Spanish;English

Identifier: ISSN0212-5633;ISSN0212-5633

ILS API ID: NSW01000844777

Source: UNSW Aleph

Call number: 720.5/121 issue 94

I'll pop up this afternoon and scan the appropriate pages.

Cheers

CNC Router Details

Hi Guys,

The CNC router at the Square House is a Roland MDX-550 and it uses a piece of software called the SRP Player.

SRP stands for Subtractive Rapid Prototyping.

There are videos tutorials online; this is one uploaded by the makers of the machine, Roland, http://www.youtube.com/watch?v=IwNbWbyWcL4

We can visit to take a look at the machine at 1pm today (Monday 21 October).

Cheers

The CNC router at the Square House is a Roland MDX-550 and it uses a piece of software called the SRP Player.

SRP stands for Subtractive Rapid Prototyping.

There are videos tutorials online; this is one uploaded by the makers of the machine, Roland, http://www.youtube.com/watch?v=IwNbWbyWcL4

We can visit to take a look at the machine at 1pm today (Monday 21 October).

Cheers

Thursday, October 17, 2013

More examples

Hi Guys,

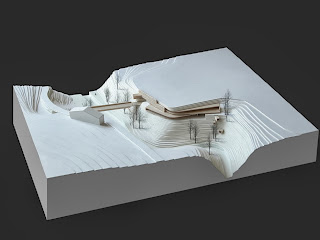

This is from one of the sites we looked at in class the other day: Le Container

A nice example of site and architecture coming together in a model.

and some other examples (just one with a site, but just to keep you thinking/inspired):

This is from one of the sites we looked at in class the other day: Le Container

A nice example of site and architecture coming together in a model.

and some other examples (just one with a site, but just to keep you thinking/inspired):

Tuesday, October 15, 2013

Filament for the 3d Printers

Hi Guys,

You can get your own filament for the 3d printers here:

https://www.bilbycnc.com.au/DispCat.asp?CatID=9&SubCatID=107

Its very reasonably priced and you can get a range of colours ... you might like to team up and share some different colours between a group of you?

Cheers

You can get your own filament for the 3d printers here:

https://www.bilbycnc.com.au/DispCat.asp?CatID=9&SubCatID=107

Its very reasonably priced and you can get a range of colours ... you might like to team up and share some different colours between a group of you?

Cheers

Sunday, October 13, 2013

Websites and Blogs from today's class

Hi Guys,

Choi sent me all of the blog's we viewed in today's class; I've put them in a new post so that they are a little easier to get to;

http://lecontainer.blogspot.com.au/

http://bldgblog.blogspot.com.au/

http://www.dezeen.com/

http://abduzeedo.com/

http://www.deathbyarchitecture.com

http://www.archdaily.com/

http://www.ted.com/

I encourage you all to visit them on a regular basis.

Cheers

Choi sent me all of the blog's we viewed in today's class; I've put them in a new post so that they are a little easier to get to;

http://lecontainer.blogspot.com.au/

http://bldgblog.blogspot.com.au/

http://www.dezeen.com/

http://abduzeedo.com/

http://www.deathbyarchitecture.com

http://www.archdaily.com/

http://www.ted.com/

I encourage you all to visit them on a regular basis.

Cheers

Wednesday, October 9, 2013

Laser cutting advice from Anthony Jones

Hi All,

Below is some advice from Anthony Jones (Design Lab) regarding problems you might be having with the new VLS3.50 laser cutter;

I would add that slowing the speed of the laser seems to have the greatest effect on cutting through the material, but be especially careful to ensure that any flames from the cut are sucked away quickly by the extraction unit ... we don't want those flames getting anywhere near the lenses and mirrors!

I've had reports back that 5mm MDF has been cut successfully, so its all in the settings.

Finally, I'll remind you that upping the material thickness beyond what the material actually is simply puts the laser out of focus and lowers its cutting performance, which upping the risk of fire, so don't be tempted to use that technique if your material isn't cutting.

Cheers

Below is some advice from Anthony Jones (Design Lab) regarding problems you might be having with the new VLS3.50 laser cutter;

·

Laptops are not connecting properly to the laser:

o The

connection problems could be due to:

-

not logged in to PC as ‘admin’ with full rights

-

incorrect model chosen during install

-

UCP installed, but actual ‘driver’ firmware not

being installed when laser connected (found new hardware wizard)

-

Won’t work with Mac, and Windows 8 may have ‘driver

not digitally signed’ errors

-

faulty or low-powered USB port

·

Material

is not being cut 100% of the way through:

o

Most

materials do vary a bit from their nominated thickness – solution is to

increase the power settings as follows:

-

in

the ULS driver, on the ‘Materials Database tab’, drag the intensity slider for

‘Vector Cutting’ till you get a result

that works.

I would add that slowing the speed of the laser seems to have the greatest effect on cutting through the material, but be especially careful to ensure that any flames from the cut are sucked away quickly by the extraction unit ... we don't want those flames getting anywhere near the lenses and mirrors!

I've had reports back that 5mm MDF has been cut successfully, so its all in the settings.

Finally, I'll remind you that upping the material thickness beyond what the material actually is simply puts the laser out of focus and lowers its cutting performance, which upping the risk of fire, so don't be tempted to use that technique if your material isn't cutting.

Cheers

Wednesday, October 2, 2013

Safe Working Procedure form to read

hi All,

Please download and read this form regarding the safe working procedure for using the VLS3.50 desktop laser cutter in room 2025:

HS026_Safe_Work_Procedure_Form_VLS350_RL.pdf

It goes over all of the items we covered in your training.

I'll have you sign my master copy next time I see you.

Cheers

Please download and read this form regarding the safe working procedure for using the VLS3.50 desktop laser cutter in room 2025:

HS026_Safe_Work_Procedure_Form_VLS350_RL.pdf

It goes over all of the items we covered in your training.

I'll have you sign my master copy next time I see you.

Cheers

Tuesday, September 17, 2013

Sunday, September 15, 2013

CREATE: UNSW Club for Making Things

Hi All,

Hopefully by now you've seen the posters ...

The Create club at UNSW is offering tutorials on using the Arduino; a good way to take your models to the next level with lighting and interactivity.

I'd encourage you to get involved.

Cheers

Hopefully by now you've seen the posters ...

The Create club at UNSW is offering tutorials on using the Arduino; a good way to take your models to the next level with lighting and interactivity.

I'd encourage you to get involved.

Cheers

Monday, September 9, 2013

Swipe Card Access Live

Hi Guys,

Your swipe cards should now give you access to our mini fab lab; They should work on the glass door at the top of the ramp on level 2.

Cheers

Your swipe cards should now give you access to our mini fab lab; They should work on the glass door at the top of the ramp on level 2.

Cheers

Sunday, September 8, 2013

Examples of Objects in Cases

Hi Guys,

Here are a few examples:

Here are a few examples:

Jeff Koons: Multiple Levels

Jeff Koons: Open Base

Marc Quinn: Refrigerated Case

Conventional Presentation Case in Museum

Damien Hirst: Case Mounted on a Wall

Damien Hirst: Shark in a Case filled with Formaldehyde.

Architectural Model of Japanese House in Glass Case

Anthony Gormley: Artists Body Encased

Anthony Gormley: Artists Body Encased ... From Projected Normals

Anthony Gormley: As Above but without the Bronze Skin

Christo and Jeanne-Claude: Wrapping

Christo and Jeanne-Claude: Wrapping Trees

Encased iPod: 3d Printing?

Rachel Whiteread: Casting

Rachel Whiteread: Casting House

EXAM in rm2034 Today

Hi All,

See you in rm2034 today for the Design Exam for assignment 2.

The exam starts at 9am and runs through the whole session ... however, at some point I'll take groups to be inducted on the new desktop laser cutter.

Cheers

See you in rm2034 today for the Design Exam for assignment 2.

The exam starts at 9am and runs through the whole session ... however, at some point I'll take groups to be inducted on the new desktop laser cutter.

Cheers

Laser Cutter Driver

Hi Guys,

Download this file to drive the laser cutter from your computer.

When installing, the type of laser is a VLS3.50

Cheers

Download this file to drive the laser cutter from your computer.

When installing, the type of laser is a VLS3.50

Cheers

Wednesday, September 4, 2013

Laser Cutter has Arrived

Hi All,

I'll do the additional induction with you all on Monday, there are a few differences between this machine and the ones in the Design Lab; so don't use it until you've been inducted and I've given you the all clear.

Feel free to drop by and check it out though...

Cheers

I'll do the additional induction with you all on Monday, there are a few differences between this machine and the ones in the Design Lab; so don't use it until you've been inducted and I've given you the all clear.

Feel free to drop by and check it out though...

Cheers

Sunday, September 1, 2013

Friday, August 30, 2013

Extension for Assignment 1

Hi Guys,

I've had a few requests for an extension for Assignment 1. They were based on a few outages of the technologies we are using. As these would have affected all of you I've decided that a class wide extension is reasonable.

The new due date for Assignment 1 is Sunday 8th of September; so an additional week.

I'll consult with you all in class on Monday to determine if we push the submission dates for Assignment 2 and 3 out a week or if we try to make the time back up.

Cheers

I've had a few requests for an extension for Assignment 1. They were based on a few outages of the technologies we are using. As these would have affected all of you I've decided that a class wide extension is reasonable.

The new due date for Assignment 1 is Sunday 8th of September; so an additional week.

I'll consult with you all in class on Monday to determine if we push the submission dates for Assignment 2 and 3 out a week or if we try to make the time back up.

Cheers

Wednesday, August 21, 2013

Independent Study; 26th August

Hi All,

Just a reminder (from the course outline) that I'll be away on the 26th of August ... so you will be required to work independently.

It's a great opportunity to get together and refine your rapid prototyping and laser cutting skills.

Cheers, see you on the 2nd of September

Just a reminder (from the course outline) that I'll be away on the 26th of August ... so you will be required to work independently.

It's a great opportunity to get together and refine your rapid prototyping and laser cutting skills.

Cheers, see you on the 2nd of September

Sunday, August 18, 2013

Today's Class

Hi Guys,

Lets meet in the level 2 lab (rm2034) at 9am; we can go from there.

Today we'll be reviewing this work in one on one meetings:

1. Complete project component list and timeline

2. Create “water-tight” digital components, laser cut components

3. Create blue foam components.

4. Create first draft assembly.

Via your blog.

While we are doing this you'll be 3d printing (rm2025), laser cutting (design lab) and assembling the components.

UPDATE: we've been given the go ahead for a desktop laser cutter (for rm2025) and I've placed the order with the supplier.

For a little background reading see the extract below for an interesting reflection on innovative representation and the resulting architecture:

Moloney, J. "3d Game Software and Architectural Education."

Auckland has established itself among the top design schools in Australasia with our students frequently successful in prestigious international competitions. Reviews by accrediting agencies often make comment on the excellence and innovation students demonstrate in drawing and model making. In my view this is due to the emphasis placed by most design studios on the close relationship between representation and the development of design ideas. The “mark - interpret - mark cycle” articulated by Daniel Herbert in relation to sketching has been extended within our design studios to the production of innovative composite drawings and malleable physical models (Herbert, 1993). While not a certainty our experience has shown that innovative representation

generally produces innovative and sophisticated architectural projects. These observations are reinforced by the work of theorist Robin Evans who in “The Projective Cast” traces the relationship between projective geometry and the generation of architectural form (Evans, 1995). In this work he proposes that the historical development of architecture has been limited by the ability to describe form on paper, and hence related to the drafting tools and techniques available at any given period.

Evans’ historical perspective has been used by the author to propose alternate strategies facilitated or made possible by the use of digital technology (Moloney, 2000). These were categorised as emergent form (using generative techniques such as cellular automata, shape grammar or genetic algorithms), immersive editing (the editing of architecture within virtual environments) and computer aided construction (the automated construction of architecture using CNC machines). These three strategies are to my mind the advantages of computing for design. While the first

involves computer programming beyond the curriculum of most schools and the later requires specialised and expensive machines, the facility to evaluate and alter architectural design - immersive editing - is within the resources of typical architecture schools.

Paper presented at the Meeting at the Crossroads. Short Paper Proceedings of the 18th Annual Conference of the Australian Society for Computers in Learning in Tertiary Education., Melbourne, Australia, 9-12 December 2001.

Cheers

Lets meet in the level 2 lab (rm2034) at 9am; we can go from there.

Today we'll be reviewing this work in one on one meetings:

1. Complete project component list and timeline

2. Create “water-tight” digital components, laser cut components

3. Create blue foam components.

4. Create first draft assembly.

Via your blog.

While we are doing this you'll be 3d printing (rm2025), laser cutting (design lab) and assembling the components.

UPDATE: we've been given the go ahead for a desktop laser cutter (for rm2025) and I've placed the order with the supplier.

For a little background reading see the extract below for an interesting reflection on innovative representation and the resulting architecture:

Moloney, J. "3d Game Software and Architectural Education."

Auckland has established itself among the top design schools in Australasia with our students frequently successful in prestigious international competitions. Reviews by accrediting agencies often make comment on the excellence and innovation students demonstrate in drawing and model making. In my view this is due to the emphasis placed by most design studios on the close relationship between representation and the development of design ideas. The “mark - interpret - mark cycle” articulated by Daniel Herbert in relation to sketching has been extended within our design studios to the production of innovative composite drawings and malleable physical models (Herbert, 1993). While not a certainty our experience has shown that innovative representation

generally produces innovative and sophisticated architectural projects. These observations are reinforced by the work of theorist Robin Evans who in “The Projective Cast” traces the relationship between projective geometry and the generation of architectural form (Evans, 1995). In this work he proposes that the historical development of architecture has been limited by the ability to describe form on paper, and hence related to the drafting tools and techniques available at any given period.

Evans’ historical perspective has been used by the author to propose alternate strategies facilitated or made possible by the use of digital technology (Moloney, 2000). These were categorised as emergent form (using generative techniques such as cellular automata, shape grammar or genetic algorithms), immersive editing (the editing of architecture within virtual environments) and computer aided construction (the automated construction of architecture using CNC machines). These three strategies are to my mind the advantages of computing for design. While the first

involves computer programming beyond the curriculum of most schools and the later requires specialised and expensive machines, the facility to evaluate and alter architectural design - immersive editing - is within the resources of typical architecture schools.

Paper presented at the Meeting at the Crossroads. Short Paper Proceedings of the 18th Annual Conference of the Australian Society for Computers in Learning in Tertiary Education., Melbourne, Australia, 9-12 December 2001.

Cheers

Sunday, August 11, 2013

Today's Class

Hi Guys,

A reminder that we'll be meeting in Lab 5 (level 3, far end) at 9am to begin the Design Exam.

From the course outline (supplements in brackets):

Week 3, 12th August: 9am to 2 pm

Design exam: 5hr exam to design house 1 (Use chronolapse to capture your work in progress. Refer to the feedback and review sheet to focus your efforts).

Independent study: complete project component list and timeline; create “water-tight” digital components, laser cut components; create blue foam components; create first draft assembly; upload digital images.

Cheers

A reminder that we'll be meeting in Lab 5 (level 3, far end) at 9am to begin the Design Exam.

From the course outline (supplements in brackets):

Week 3, 12th August: 9am to 2 pm

Design exam: 5hr exam to design house 1 (Use chronolapse to capture your work in progress. Refer to the feedback and review sheet to focus your efforts).

Independent study: complete project component list and timeline; create “water-tight” digital components, laser cut components; create blue foam components; create first draft assembly; upload digital images.

Cheers

Thursday, August 8, 2013

OHS documents to read for Laser Cutter

Hi Guys,

Read these and next time you go down to the Design Lab you can sign the OHS documents and then you are good to go:

www.russelllowe.com/arch7112_2013/IDLabManual2009.pdf

www.russelllowe.com/arch7112_2013/RA_Universal Laser_ILS9150D_V_01.pdf

www.russelllowe.com/arch7112_2013/SWP_Universal Laser ILS9150_V_01.pdf

Cheers

Read these and next time you go down to the Design Lab you can sign the OHS documents and then you are good to go:

www.russelllowe.com/arch7112_2013/IDLabManual2009.pdf

www.russelllowe.com/arch7112_2013/RA_Universal Laser_ILS9150D_V_01.pdf

www.russelllowe.com/arch7112_2013/SWP_Universal Laser ILS9150_V_01.pdf

Cheers

Monday, July 29, 2013

Design Workshop Shop Opening Hours

Hi All,

As the title says:

Cheers

(If you buy cardboard or blue foam from the shop please leave the prices you paid in the comments below).

As the title says:

Cheers

(If you buy cardboard or blue foam from the shop please leave the prices you paid in the comments below).

Subscribe to:

Posts (Atom)